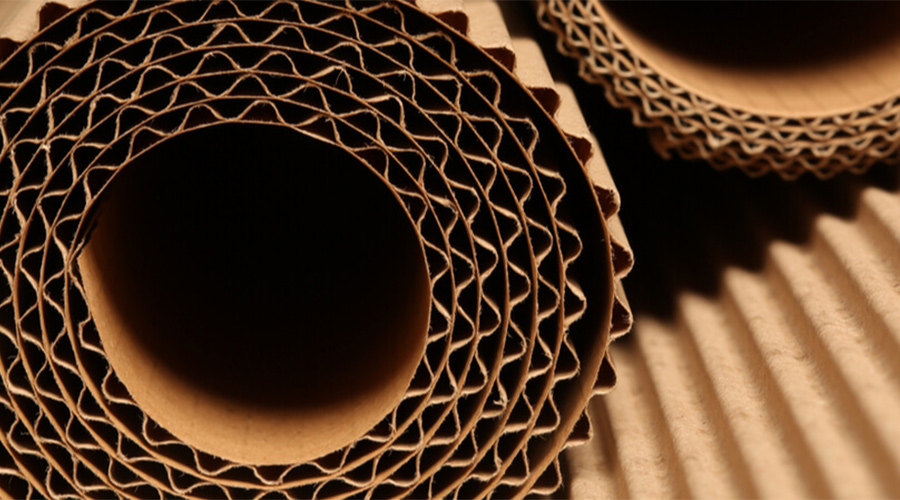

I kaʻO kaʻoihana paʻa, ka hana a me ka hanaʻana o nā kāleka corrugated e koi ai i nā koi kiʻekiʻe ma ka paleʻana i ka paleʻana, paʻakikī a me ka paʻakikī o nā mea hanaʻokiʻoki. Ma luna o nā makahiki, ua lilo i ka carbide carbide i lilo i mea koho noNā Kūlana CORRUGATEDMa muli o kona kino kino maikaʻi loa a me nā waiwai kūpono. Ma kēiaʻatikala, nānā mākou i ka mea e kū ai i ka carbide carbide mai ka lehulehu e like me ke koho maikaʻi loa no nā clitter slity.

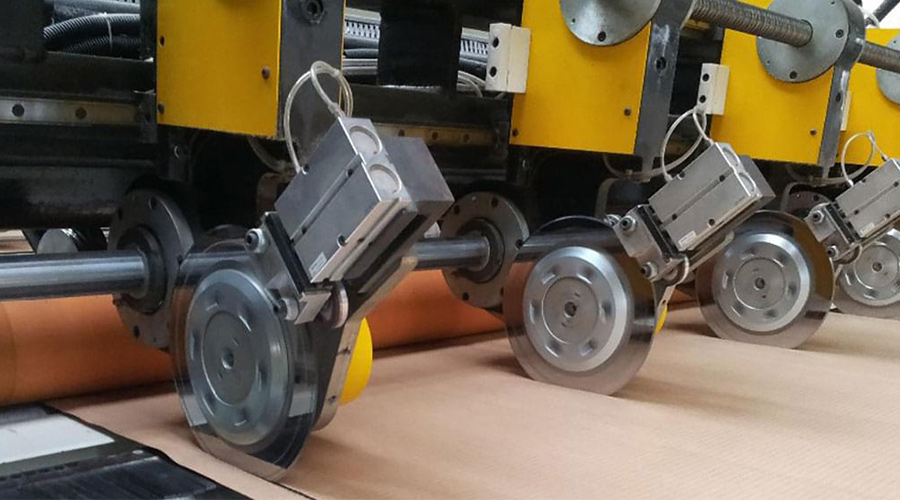

ʻO nā kāpena hoʻopunipuni,ʻikeʻiaʻo iaʻo Tungsten Carbide, he mea i hanaʻia ma o kahi kaʻina metallirgical. ʻO ia ka mea i hana i ka carbide a me nā condert a me nā mea hao'ē aʻe, a loaʻa i kahiʻano o nā mea maikaʻi loa, kiʻekiʻe a me nā pale kiʻekiʻe. ʻO kēia mau waiwai e hana i nā cunge carbide carbide cute clades i ka hana maikaʻiʻana i nā pahu corrugated, he paʻakikī kiʻekiʻe.

ʻO ke kaʻinaʻokiʻoki o nā pahu corrugated e koi i nā'āpana me nā pale kiʻekiʻe kiʻekiʻe. Uaʻoi aku ka maikaʻi o nā mea hana Trungsten Carbide i nā pale o nā mea maʻamau ma mua o nā mea kanu maʻamau e like me ke kila kiʻekiʻe. ʻO kēia keʻano o ka laweʻana i nā crabide carbide carbide i kahi ola lawelawe e loaʻa ana, e hopena ana i ka emiʻana o ka downtime a hoʻonuiʻia i ka huahana. No kaʻoihana kāwele,ʻo ia ka mea e pili ana i nā kumukūʻai haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa a me nā kiʻekiʻe kiʻekiʻe.

ʻO ka paʻakikī kiʻekiʻeʻo Trungsten i ke kumu kiʻekiʻe o ke kālā he kumu nui no ke aha he mea kūpono loa no ke kāʻeiʻana i nā pahu corrugated. ʻO ka paʻakikī keʻano o ka hiki ke pale i kahi mea e pale aku ai i nā kiʻi a me nāʻano. I ka wā eʻoki ana i nā pahu corrugated, pono e pono ka pale i ka ikaika kiʻekiʻe a me ka pā. ʻOi aku ka paʻakikī o ka paʻakikī o ka Carbide ma mua o nā mea'ē aʻe eʻoki ana i nā mea kanu pale

Ma kahi o ka paleʻana i ka pale a me ka paʻakikī,ʻo nā kāpena tungsten he maikaʻi maikaʻi loa. I ke kaʻinaʻokiʻana, ua kīna keʻili i ka wela, a ināʻaʻole hiki ke hōʻoleʻia ka wela i ka manawa, e alakaʻiʻia ai e ke ana i ka wā kā ke makapoe. ʻO ka laweʻana i ka Thermal of Turnsen Carbide e kōkua i ka ho'ēmiʻana i ka hopena o ka wahī i ka wā o kaʻokiʻana, e hoʻomau ana i ka paʻaʻana o kaʻili aʻokiʻoki i ka paʻaʻana.

Hiki i nā mea kīwīʻo Tungsten ke loaʻa i nā hopena kūpono a me ka hoʻoponoponoʻana i nā hopena i hanaʻia i ka hopena o ke kaʻina hana corrugated. He mea nui kēia e pale i nā mea mai ka hoʻokaʻawaleʻana ma waena o nā papa a iʻole e hoʻopiʻi ana ma nā kihi. ʻO ka mea nui ma Ultrasonic Covice Meltrasoranic

I ka hōʻuluʻuluʻana,ʻo ka carbide kākelaʻo ia ka mea maikaʻi loa nocorrugated pepa cuteʻokiMa muli o kona paʻakikī paʻakikī, kiʻekiʻe lole kiʻekiʻe, ikaika kiʻekiʻe a me ka ikaika o ke karmal. ʻAʻole wale ia e hoʻomaikaʻi i ka huahana a hōʻemi i nā kumukūʻai mālama, akā e hōʻoia hou i kaʻokiʻana i ka maikaʻi a me ka pololei. Me ka hoʻomohala mauʻana o ka hoʻolālāʻana i ka hoʻolālāʻana a me nāʻepekema waiwai,ʻo ka noiʻana o nā mea e hiki ai i kaʻoihana ke loaʻa i ka hopena

Hope mai, e hoʻomau mākou i ka hoʻolahaʻana i kaʻike, a hiki iāʻoe keʻike i nāʻike hou aʻe ma kā mākou pūnaewele (Stenintotool.com) Blog.

ʻO kaʻoiaʻiʻo, hiki iāʻoe ke hoʻolohe i kā mākou hoʻolaha pūnaewele pūnaewele: